Product Details

Products Name:M6 Multi-purpose Machine

Key Feature:Used for cutting, drilling and milling

Electronic variable spindle speeds

Near silent running, Integral splash guard

Metric and imperial thread cutting

Full range of accessories available

Converts to a multi-purpose machine with the milling attachment

Specifications

Cutting (Lathe)

Swing over bed 250 mm

Distance between centers Model 400 400 mm

Model 550 550 mm

Hole through spindle 20 mm

Spindle taper MT3

Tailstock taper MT2

Spindle speed (6 step) 125-2000 rpm

Compound travel 75 mm

Cross slide travel 110 mm

Motor output power 550 W

Thread range Metric version 0.4-3.0 mm ( 12 threads pitches)

Imperial version 10-44 TPI ( 8 threads pitches)

Overal dimension (LxWxH) Model 400 1040x640x570 mm

Model 550 1140x600x450 mm

Weight (Net/Gross) Model 400 125/160 kg

Model 550 145/180 kg

Packing Size (LxWxH) Model 400 1040x640x570 mm

Model 550 1200x640x570 mm

Drilling &Milling

Drilling capacity 13 mm

Headstock travel (Z) 180 mm

Spindle taper MT3 or R8

Head tilt 25°L, 45°R

Motor output power 350 W

Spindle speed Low range 100-1100 ±10% rpm

High range 100-2500 ±10% rpm

Overal dimension (LxWxH) 500x500x700 mm

Packing size (LxWxH) 550x550x730 mm

Weight (Net/Gross) 50/68 kg

M6/400 Overal dimension (LxWxH) 1100x680x860 mm

M6/550 Overal dimension (LxWxH) 1200 680x860 mm

Optional Accessories

|

Serial No. |

Item Description |

Picture |

Suitable for Models |

|

S/N:10239 |

Stand for Model 550 |

|

C6,C6B,M6 |

|

S/N:10018 |

Stand for Model 550

Overall demension: 1060*440*850mm |

|

C6,C6B,SC6,M6 |

|

S/N:10019 |

Steady rest |

|

C6,C6B,SC6,M6 |

|

S/N:10020 |

Follow rest |

|

C6,SC6,C6B,M6 |

|

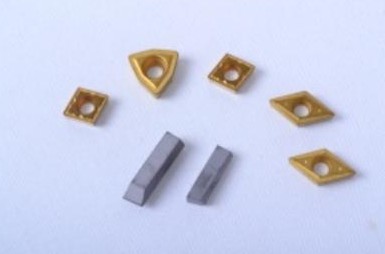

S/N:10022 |

Cutter 11 pieces set

DIN 4971R Straight cutter

DIN 4972R Angle cutter

DIN 4973R Bore cutter

DIN 4974R Bore cutter

DIN 4975 Tip cutter

DIN 4976 Wide edge cutter

DIN 4977R Right external turning cutter

DIN 4978R External turning cutter

DIN 4980L Left angle cutter

DIN 4980R Right angle cutter

DIN 4981R Cutter |

|

C4A,C4B,SC4,C6,

C6B,SC6,SM4,M6 |

|

S/N:10023 |

Face plate ¢220mm |

|

C6,C6B,SC6,M6 |

|

S/N:10023A |

Clamping kit for face plate |

|

C6,SC6,C6B,C8,M6,M8 |

|

S/N:10024 |

Rolling center MT#2

|

|

C6,SC6,C4A,SC4,

C6B,C8,SM4,M6,M8 |

|

S/N:10025 |

4-jaw chuck ¢125mm |

|

C6,C6B,SC6,SX4 |

|

S/N:10025A |

4-jaw chuck ¢125mm with flange |

|

C6,SC6,C6B,M6 |

|

S/N:10026 |

Quick change cutter rest |

|

C6,SC6,C6B,M6 |

|

S/N:10027 |

Tailstock chuck

Dia.13mm+MT#2 |

|

C4A,C4B,SC4,C6,C6B,

SC6,C8,SM4,M6,M8 |

|

S/N:10060 |

Vertical slider

Slot size 50mm |

|

C6B,C6,SC6 |

|

S/N:10063 |

Wood toolrest with center |

|

C6B,C6,SC6 |

|

S/N:10131B |

Grinding attachment

Spindle speed 0-6000±10%rpm

Wheel size 80*20*10mm

Motor output power 250W

Net/Gross weight 4/5kg |

|

C6,SC6,C6B,M6 |

| S/N:10131-1 |

Wheel replacement |

|

C6,SC6,C6B,M6 |

|

S/N:10149 |

Mill chuck set(metric)

Chuck dia. 4, 6, 8, 10, 12, 14, 16mm |

|

M6,C6B,C6,SC6 |

|

S/N:10149A |

Mill chuck set(Imperial)

Chuck dia. 4, 6, 8, 10, 12, 14, 16mm |

|

M6,C6B,C6,SC6 |

|

S/N:10151 |

DRCD kit |

|

C6,SC6,C6B,M6 |

|

S/N:10198 |

Lux cutter set with box 10x10 mm

DIN 4971R Straight cutter

DIN 4972R Angle cutter

DIN 4973R Bore cutter

DIN 4974R Bore cutter

DIN 4975 Tip cutter

DIN 4976 Wide edge cutter

DIN 4977R Right external turning cutter

DIN 4978R External turning cutter

DIN 4980L Left angle cutter

DIN 4980R Right angle cutter

DIN 4981R Cutter |

|

C4A,C4B,SC4,C6,C6B,SC6 |

|

S/N:10201 |

Cutting set 10mm(Tin Coated)

DIN 4977R Right external turning cutter

DIN 4980L left cutter

DIN 4980R Right cutter

DIN 4975R Thread cutter

DIN 4981R Cutter |

|

C4A,C4B,SC4,C6,C6B,SC6 |

|

S/N:10201-1 |

Tip replacement |

|

C4A,C4B,SC4,C6,C6B,SC6 |

|

Serial No. |

Item Description |

Picture |

Suitable for Models |

|

S/N:10036 |

Quick vice100mm |

|

U1,SU1,X2,X2L,

SX2,SX2L,X2P,X3,

X3L,SX3,SX3L,M6 |

|

S/N:10037 |

MT3 Mill chuck set(metric)

Chuck dia. 4, 6, 8, 10, 12, 14, 16mm |

|

U1,SU1,X2,X2L,

SX2,SX2L,X2P,X3,

X3L,SX3,SX3L,SX4,M6 |

S/N:10038

S/N:10039

S/N:10040

S/N:10041

S/N:10042

S/N:10043

S/N:10044

S/N:10045 |

2 Flute Hss end mill ¢4mm

2 Flute Hss end mill ¢6mm

2 Flute Hss end mill ¢8mm

2 Flute Hss end mill ¢10mm

2 Flute Hss end mill ¢12mm

2 Flute Hss end mill ¢14mm

2 Flute Hss end mill ¢16mm

¢4-16 mm |

|

X1,SX1,X2,X2L,

SX2,SX2L,X2P,XN2 |

|

S/N:10056 |

Drill bit 1-13 mm 25 pcs |

|

X2,X2L,SX2,SX2L,

X2P,X3,X3L,SX3,SX3L,

Z1,Z2,Z3,Z4 |

|

S/N:10057 |

Drill bit Tin coated 25 pcs |

|

X2,X2L,SX2,SX2L,

X2P,X3,X3L,SX3,SX3L,

Z1,Z2,Z3,Z4 |

|

S/N:10058 |

Drill bit 1-10 mm 19 pcs |

|

X2,X2L,SX2,SX2L,

X2P,X3,X3L,SX3,SX3L,

Z1,Z2,Z3 |

|

S/N:10059 |

Drill bit Tin coated 19 pcs |

|

X2,X2L,SX2,SX2L,

X2P,X3,X3L,SX3,SX3L,

Z1,Z2,Z3 |

|

|

4 Flute HSS end mill (metric 7 pcs)

4 Flute HSS end mill (metric 6pcs) |

|

X1,SX1,X2,X2L,SX2,

SX2L,X3,X3L,SX3,SX3L |

|

|

4 Flute HSS end mill (imperial 6 pcs)

4 Flute HSS end mill (imperial 8 pcs) |

|

X1,SX1,X2,X2L,SX2,SX2L,

X2P,X3,X3L,SX3,SX3L |

|

S/N:10094 |

Rotary table 100mm |

|

U1,SU1,SX0,X2,X2L,

SX2,SX2L,X2P,X3,

X3L,SX3,SX3L,M1 |

|

S/N:10094-1 |

Dividing plate for S/N:10094 |

|

U1,SU1,X2,X2L,

SX2,SX2L,X2P,X3,

X3L,SX3,SX3L,M1 |

|

S/N:10094-2 |

Tailstock for S/N:10094 |

|

U1,SU1,X2,X2L,

SX2,SX2L,X2P,X3,

X3L,SX3,SX3L,M1 |

|

S/N:10109 |

Vice width 80mm |

|

X2,X2L,SX2,SX2L,X2P,

X2P,X3,X3L,SX3,SX3L |

S/N:10119

S/N:10120

S/N:10121

S/N:10122

S/N:10123

S/N:10124

S/N:10125

S/N:10126 |

Collet MT3 ¢4mm

Collet MT3 ¢6mm

Collet MT3 ¢8mm

Collet MT3 ¢10mm

Collet MT3 ¢12mm

Collet MT3 ¢14mm

Collet MT3 ¢16mm

Collet MT3 ¢4-16mm |

|

X2,X2L,SX2,SX2L,X2P |

|

S/N:10127 |

Stub milling machine arbor for

For slitting saw hole ¢16mm |

|

X2,X2L,SX2,SX2L,

X2P,X3,X3L,SX3,SX3L |

|

S/N:10128 |

Boring arbor with boring cutter

MT#3 |

|

X2,X2L,SX2,SX2L,

X2P,X3,X3L,SX3,SX3L |

|

S/N:10129 |

Stub milling machine arbor for For slitting saw, hole ¢16mm |

|

X2,X2L,SX2,SX2L,

X2P,X3,X3L,SX3,SX3L |

Review

|